Global procurement managers know that China is the world’s leading manufacturing hub for juvenile products. To buy wholesale baby strollers and other large items (cribs, high chairs, etc.), follow a structured sourcing strategy. First, define your product specs and market needs (safety, style, price). Then identify and vet reputable baby product suppliers in China, negotiate terms (MOQ, lead time, branding), and manage quality, shipping, and compliance. This comprehensive guide covers each step with practical tips.

Step-by-Step Guide to Sourcing Baby Strollers and Large Baby Items

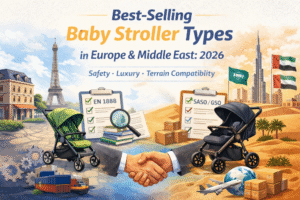

- Define Product Requirements & Demand. List technical specifications (dimensions, weight, materials) and safety standards. Determine what certifications your market needs (e.g. EN 1888 for EU strollers, ASTM F833 for US). Plan branding/customization (logos, colors) and packaging requirements. Estimate order volume and timelines: large factories often expect initial orders of 500–1,000+ units per model, with sample and production lead times of 4–8 weeks plus shipping. Knowing your budget and timeline upfront streamlines negotiations.

- Identify Potential Suppliers. Search major B2B platforms and trade fairs for baby product suppliers in China. Filter out vendors who refuse to share licenses or factory info, quote unrealistically low prices, or demand tiny MOQs from new accounts. Focus on Chinese manufacturers (not trading companies) for custom products; note that suspiciously low MOQs (e.g. <100 units) often indicate middlemen.

- Vet and Verify Suppliers. Carefully evaluate each candidate’s credentials: ask for business licenses, factory photos, and client references. Check production capacity (e.g. factory size >5,000 m², ≥50 employees indicates scalability). Key criteria include:

- Certifications & Testing: Require valid EN 1888 (EU), ASTM F833 or CPC/CPSC (US), ISO 9001 (quality), and any market-specific marks. Always obtain verifiable certificates and third-party test reports (e.g. SGS, Bureau Veritas) for safety features.

- Quality Assurance: Implement multi-layer checks – request pre-production samples, conduct virtual or onsite factory audits, and hire third-party inspectors to verify quality at each production stage.

- Performance Metrics: Look for high on-time delivery rates (≥95%) and fast communication. A high reorder percentage (e.g. >40%) indicates customer satisfaction.

- Factory Audits & Compliance: If possible, conduct on-site visits or virtual tours to confirm machinery, worker skills, and cleanliness. Confirm the supplier has experience exporting to target markets (check for previous shipments or compliance history).

- Request and Test Samples. Ordering samples is critical. Inspect each stroller sample in person or via video: test the fold/unfold mechanism, wheel durability, frame strength, brakes, harness security and overall assembly. Check comfort and functionality on uneven surfaces. Resolve any design or safety issues early. Established suppliers may charge $50–$200 per sample (shipping included) but often refund this fee on the full order. If the design is final, lock sample specifications into the purchase contract to prevent later substitutions.

- Negotiate Terms. Use your leverage wisely: emphasize potential order volumes, repeat business or long-term partnership to get better pricing and terms. Compare quotes from multiple suppliers to benchmark costs. Be prepared to walk away if a supplier won’t meet your basic needs. Key negotiation points:

- MOQ: Clarify minimum order quantities. Large factories typically require 500–1,000+ units/model, while smaller mills may accept ~300. Negotiate lower MOQs for a trial run, but expect a higher unit price or consolidation of SKUs.

- Price and Payment: Agree on unit price including packaging. Typical terms are 30% deposit, 70% at shipment (or L/C). Avoid 100% prepayment on first orders.

- Lead Time: Confirm production lead time (often 30–60 days after sample approval) and add buffer for shipping (15–45 days by sea). Consider air freight for urgent restocks (5–10 day transit but 3–5× the cost).

- Customization and Branding: Specify logo placement, color schemes, packaging design, and any custom features. Ensure the factory can handle your private‐label requirements.

- Contract Details: Draft a detailed agreement covering product specs, quality standards (AQL limits), compliance requirements, penalties for defects/delays, and dispute resolution. Include clauses for sample approval, change orders, and after-sales support.

Key Criteria When Evaluating Chinese Exporters

When choosing a Chinese manufacturer or exporter, consider:

- Experience & Scale: Choose suppliers with a proven track record in baby products. Experienced exporters often have established OEM/ODM lines and can handle bulk strollers or cribs.

- Certifications: Verify compliance with all relevant safety standards. For strollers, this means EN 1888 for Europe and ASTM F833 (or the latest ASTM F833-21) for the US. Also look for a CPC (Children’s Product Certificate) for the US market. Ask to see actual certification documents, not just claims.

- Quality Testing: Require third-party test reports on seat restraints, braking, and materials. Some vendors will share SGS/BV reports for flammability, strength, and toxicology. Regular testing of production batches protects your brand.

- Factory Audits: Use inspection agencies to audit factories. Check that equipment, training and processes match the supplier’s claims. A clean, organized factory with active production (not just a showroom) is a good sign.

- Performance Metrics: Suppliers often showcase on-time delivery rates and repeat order rates on their profiles. A ≥95% on-time record and high reorder percentage (>40%) suggest reliability.

- Communication: Responsive, clear communication is essential. Leading exporters reply within hours to inquiries. Slow or unclear responses can signal trouble.

Negotiating MOQs, Lead Times, and Branding

Effective negotiation balances cost with your needs. Key tips:

- MOQ & Pricing: Understand that very low MOQs (e.g. under 100) are unusual for manufacturers of strollers and may indicate a trading company. If you need a small trial quantity, expect to pay a higher unit price or combine models to meet a supplier’s MOQ. Use volume discounts as leverage: larger batch sizes usually yield lower per-unit prices.

- Lead Times: State your expected delivery schedule and see if the supplier can meet it. After sample approval, production is typically 30–60 days. Include production milestones and shipping deadlines in your contract. Suppliers with fast response times (≤6 hours) often coordinate more efficiently.

- Payment Terms: Negotiate terms that protect you. A 30/70 split (before/after shipment) or using Trade Assurance/Letter of Credit is standard. Never agree to full payment before production without strong guarantees.

- Branding & Customization: Confirm early whether the factory can print your logo, use your packaging design, or adjust product colors. Custom features may raise the MOQ or unit cost. Be clear about artwork quality and materials so that your brand is represented correctly.

- Contract Clauses: In writing, cover all expectations. Include clauses for payment terms, delivery deadlines, quality standards, required test reports (e.g. certificates), and how to handle defects or non-compliance. Specify your target MOQ, product dimensions, components, and labeling requirements. This clarity avoids confusion later.

International Shipping and Regulatory Compliance

When importing large baby items, logistics and compliance are critical:

- Shipping Method: For bulk baby strollers, sea freight is usually most cost-effective. Typical transit is 15–45 days to major markets (e.g. 15–30 days to the US East/West Coast or Europe). Air freight (5–10 days) is faster but can cost 3–6 USD/kg. Choose based on urgency, cost, and product size; strollers with bulky frames often ship by sea.

- Freight Forwarding: Use a reputable forwarder experienced in baby products. They handle booking, consolidation (to reduce costs), cargo insurance, and help navigate customs. Suppliers may offer FOB or CIF terms; evaluate which gives you more control and cost transparency.

- Customs Documentation: Prepare complete paperwork: commercial invoice, detailed packing list, bill of lading or air waybill, and certificate of origin if needed. Importantly, include all test reports and compliance certificates (e.g. lab tests for EN1888/ASTM) with the shipment. Ensure the correct HS code (usually 8715.00.00 for strollers) is declared to calculate duties correctly. As a guideline, US duties on strollers are ~0–4.5%, EU ~2–3%, UK ~4–6%.

- Regulatory Standards: Baby strollers must meet strict safety standards before they can be sold abroad. In the EU/UK, EN 1888 tests stability, entrapment, durability, etc. In the US, ASTM F833 (latest version F833-21) defines performance and labeling requirements to minimize hazards. China’s own CCC/3C mark may also apply for domestic sales. Always verify that your supplier’s products have passed the relevant tests.

- Labeling & Safety: Check local labeling laws. For example, US imports need a Children’s Product Certificate (CPC) and a tracking label with factory info. EU items need CE or UKCA marking, user manuals in local languages, and warning labels. Ensure these are in your purchase order.

- Inspection at Destination: Upon arrival, plan for random quality checks or use local labs to confirm compliance before products reach consumers. This final check guards against costly recalls or fines.

Trend Analysis and Aligning with Market Demand

Procurement isn’t just about cost — it’s about stocking products that sell. Smart buyers align purchases with market trends:

- Monitor Market Trends: Use market reports, social media, and customer feedback to identify popular features and styles. Tools like surveys or industry forums can pinpoint which stroller types (lightweight umbrella strollers, all-terrain joggers, travel systems with car seats, etc.) yield the best margins. Note demographic differences: urban parents may prefer compact foldability, while others want premium all-in-one designs.

- Competitor and Sales Data: Analyze which models are flying off your shelves or online marketplace. If a specific baby gear item suddenly becomes a bestseller, increase your restock orders quickly. Conversely, if an item lags, cut back to avoid excess inventory. Being agile prevents overstock and keeps inventory fresh.

- Innovation and Differentiation: Stay aware of emerging trends (e.g. eco-friendly materials, smart features like phone app integration, or unique color patterns) and adjust your sourcing accordingly. Having a differentiated product range can give you a competitive edge in a crowded market.

- Supplier Collaboration: Share insights with your suppliers. They often have in-house R&D and can suggest new models or improvements aligned with market demand. Long-term partners may even develop exclusive variants for you.

Summary

Sourcing baby strollers and other large infant products from China can yield great value if done methodically. Start with clear product specs and market research, then find and vet baby product suppliers in China through reputable platforms or trade fairs. Verify factory credentials (certifications, capacity, quality processes) and test samples thoroughly. Negotiate MOQs, pricing, lead times and branding details up front. Manage production with staged inspections and choose the right shipping methods. Finally, ensure all products meet regulatory standards (EN 1888, ASTM F833, etc.). By aligning orders with real market trends and maintaining strict quality control, B2B buyers can successfully buy wholesale baby strollers and baby gear from Chinese exporters and build a competitive product lineup.