In the infant care market, disposable diapers are essential daily necessities, and their quality and performance directly impact consumer satisfaction and brand reputation. For procurement professionals, selecting high-quality disposable diapers is not only about cost-effectiveness but also about supply chain stability and market competitiveness. This article will delve into the materials and manufacturing processes of disposable diapers, analyzing their impact on product performance and providing a scientific selection guide for procurement professionals.

1. Introduction: The Importance of Materials and Manufacturing

The performance of disposable diapers largely depends on their materials and manufacturing processes. High-quality materials ensure the diaper’s absorbency, breathability, and safety, while advanced manufacturing processes enhance production efficiency, reduce costs, and ensure consistent product quality. Procurement professionals must consider both materials and manufacturing when making purchasing decisions to achieve the best outcomes.

2. Disposable Diaper Materials: The Foundation of Performance and Safety

The materials used in disposable diapers directly affect their absorbency, breathability, comfort, and safety. Below are the common materials found in disposable diapers and their characteristics:

2.1 Superabsorbent Polymers (SAP)

- Function: SAP is the core material in the absorbent layer, capable of quickly absorbing and locking in large amounts of liquid to prevent rewet.

- Advantages: High absorption capacity (up to hundreds of times its own weight), rapid liquid lock-in, and a dry surface.

- Procurement Considerations: The quality and quantity of SAP directly impact the diaper’s absorbency. When procuring, focus on SAP’s absorption rate, speed, and gel strength.

2.2 Non-woven Fabrics

- Function: Non-woven fabrics are used in the top and bottom layers of the diaper to guide liquid, provide a soft touch, and ensure breathability.

- Advantages: Soft and skin-friendly, breathable, and highly absorbent.

- Procurement Considerations: The weight, fiber type, and processing of non-woven fabrics affect their performance. Choose hydrophilic, soft, and non-irritating fabrics.

2.3 Breathable Films

- Function: Breathable films are used in the bottom layer to prevent liquid leakage while allowing air circulation.

- Advantages: Waterproof yet breathable, reducing moisture and preventing diaper rash.

- Procurement Considerations: The size and uniformity of the micropores in the film are crucial. Ensure a balance between breathability and waterproofing.

2.4 Elastic Materials

- Function: Elastic materials are used in the waist and leg areas to provide a snug fit and prevent leaks.

- Advantages: Good elasticity, comfortable fit, and leak prevention.

- Procurement Considerations: Focus on the elasticity and durability of the materials. Choose highly elastic and aging-resistant options.

3. Disposable Diaper Manufacturing: Ensuring Efficiency and Quality

The manufacturing process of disposable diapers directly impacts product quality and production efficiency. Advanced processes ensure consistency, reduce defect rates, and improve efficiency. Below are the key aspects of diaper manufacturing:

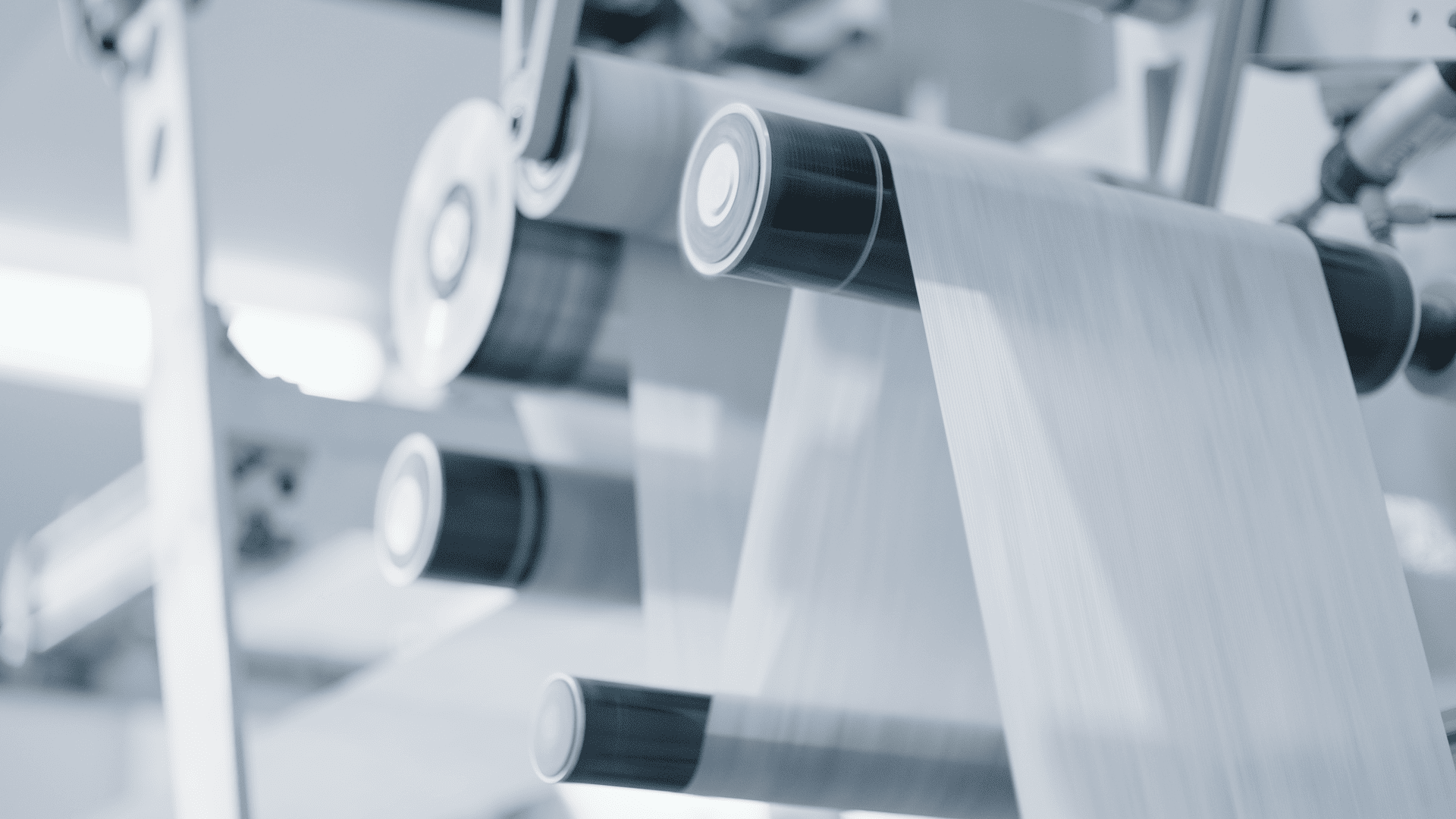

3.1 Automated Production Lines

- Advantages: Automated lines enable high-speed, continuous production, improving efficiency and product quality.

- Procurement Considerations: Check if the supplier uses advanced automation equipment, such as high-speed forming machines and automatic packaging systems.

3.2 Quality Control

- Measures: A strict quality control system, including raw material inspection, in-process monitoring, and final product testing.

- Procurement Considerations: Ensure the supplier is ISO-certified and has comprehensive quality inspection equipment and procedures.

3.3 Environmentally Friendly Processes

- Trend: Use of eco-friendly materials and processes to reduce carbon footprint and waste.

- Procurement Considerations: Check if the supplier uses renewable materials and holds environmental certifications (e.g., FSC certification).

4. Impact of Materials and Manufacturing on Diaper Performance

4.1 Absorbency

- Material Impact: The content and quality of SAP directly determine absorption capacity.

- Manufacturing Impact: The pressing process of the absorbent core and the uniformity of SAP and pulp mixing affect liquid dispersion speed.

4.2 Breathability

- Material Impact: The micropore design of breathable films influences air circulation.

- Manufacturing Impact: The processing of breathable films affects the uniformity and stability of micropores.

4.3 Comfort

- Material Impact: The softness and skin-friendliness of non-woven fabrics.

- Manufacturing Impact: The sewing process of the fastening system and the adhesive strength of the hook-and-loop fasteners.

4.4 Safety

- Material Impact: The purity and non-toxicity of raw materials.

- Manufacturing Impact: Hygiene control and disinfection measures during production.

5. Procurement Advice: Scientifically Selecting Diaper Suppliers

5.1 Evaluate Supplier Strength

- Considerations: Company history, R&D capabilities, production scale, and market share.

- Advice: Choose suppliers with years of experience, independent R&D capabilities, and large-scale production.

5.2 Focus on Product Quality

- Considerations: Product certifications, test data, and customer feedback.

- Advice: Request relevant quality certifications and test reports from suppliers and understand their market reputation.

5.3 Consider Cost-Effectiveness

- Considerations: Product price, production efficiency, and supply chain stability.

- Advice: Balance product quality and price to select suppliers with high cost-effectiveness.

5.4 Emphasize Sustainability

- Considerations: Eco-friendly materials, green processes, and carbon footprint.

- Advice: Choose suppliers committed to sustainable development to align with market trends and consumer demands.

6. Conclusion: Materials and Manufacturing Determine Procurement Value

The materials and manufacturing processes of disposable diapers are critical factors that procurement professionals cannot overlook. High-quality materials ensure product performance and safety, while advanced manufacturing processes enhance production efficiency and quality stability. When selecting disposable diapers, procurement professionals should comprehensively consider the supplier’s strength, product quality, cost-effectiveness, and sustainability to make the best procurement decisions.

7. Call to Action

If you are looking for high-quality disposable diaper suppliers, please feel free to contact us. We have years of production experience, advanced manufacturing technology, and a strict quality control system, dedicated to providing customers with premium products and services. We look forward to collaborating with you to create a better future!

This translation maintains a professional tone, technical accuracy, and clear structure, making it suitable for procurement professionals seeking insights into disposable diaper materials and manufacturing processes.